We are able to create any level of surface roughness or surface accuracy according to customer needs, ranging from ultra-mirror finishing through to satin finishing and engraving. Using these pattern adjustment techniques enables us to enhance roll functionality.。

Precision grinding

We grind high-precision coating rolls, casting rolls, and other rolls that are used in optical, battery, and other manufacturing industries. We can achieve roll finishing up to a maximum precision level of 2/1,000 mm (in terms of roundness, cylindricity, and runout). (The level of precision differs according to the size and shape of rolls.) We also ensure surface smoothness as well as precision. We can also grind rolls with bearings mounted. For details, please consult with us. In addition, we also handle a variety of crowning (such as radial crowning and tapered crowning).

300 mm dia. x 1,800 mm x 2,500 mm

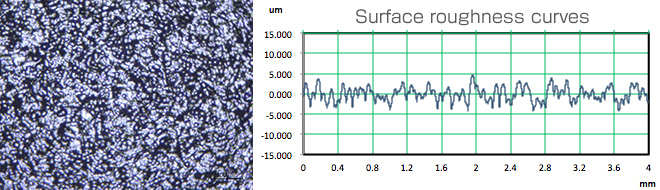

Runout precision: 1.1 μm, Surface roughness: Rmax 0.775s Ry 0.630

Runout precision: 1.1 μm, Surface roughness: Rmax 0.775s Ry 0.630

Runout chart

Surface roughness chart

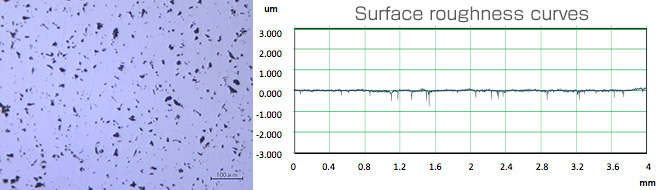

Mirror finishing

We can finish plated roll surfaces up to a level of an ultra-mirror finish with a surface roughness of Rmax 0.05S or lower. Our ultra-mirror finishing has been used for a large number of casting rolls, polishing rolls, cooling rolls, heating rolls, stretching rolls, precision coating rolls, and rolling rolls for forming films and sheets that attach greater importance to transparency.

In order to enhance the transparency of optical films, we handle mirror finishing that removes fine grinding marks that cannot be detected with a surface roughness tester. (We can also inspect for fine grinding marks by using special light source irradiation.)

Vertical grinding machine: 10 units (800 mm diameter × 4,000 mm long, 700 mm diameter × 5,000 mm long, etc.)

Vertical grinding machine

Factory dedicated to vertical grinding

Mirror finishing

Mirror-finished roll

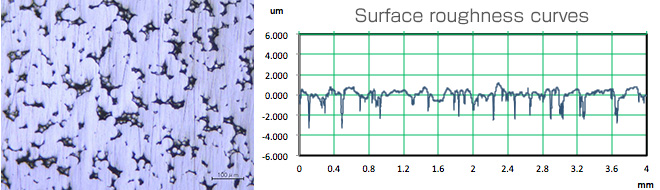

Satin finishing (matte finishing)

Satin finishing is a method for finishing roll surfaces up to a state like pear skin surfaces by using sandblasting or other means. Roll surfaces with any level of surface roughness can be created by taking measures such as changing the grit size or plating method. A large number of our satin-finished rolls are used as casting rolls for matte finishing in film production lines and cooling rolls that attach greater importance to releasability.

Combining satin finishing with Chroston also makes it possible to adjust glossiness as well as surface roughness.

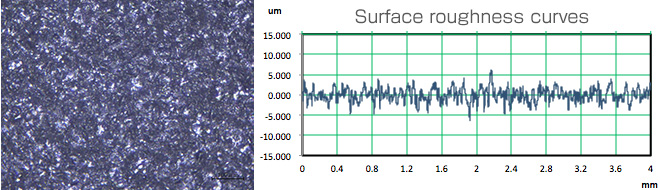

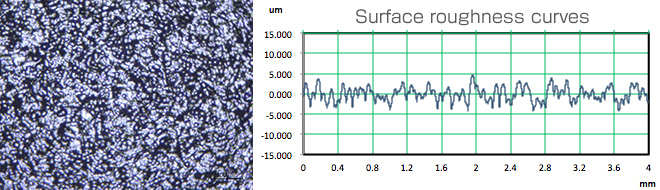

Matte finish [1]

Matte finish [2]

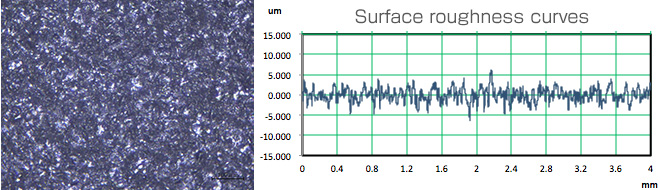

Semimatte finish

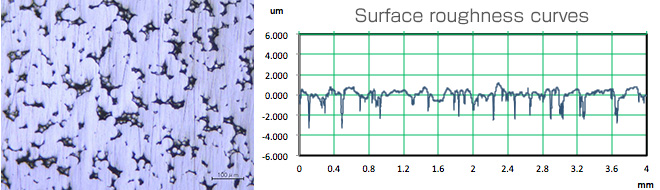

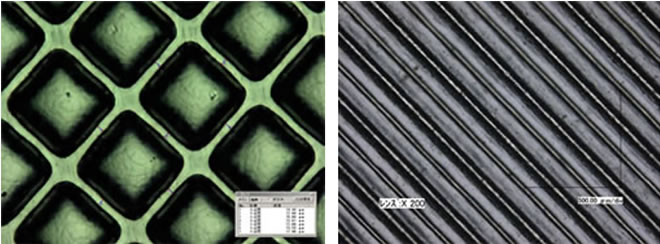

Semimatte finishing is a method for finishing roll surfaces to create glossy surfaces with air pockets. Our semimatte finishing has been used to both prevent blocking on lamination rolls and maintain the transparency of films or sheets.

Semimatte finish

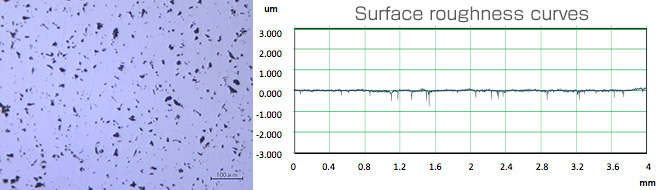

Mirror pocket finishing

We recommend that mirror pocket finishing be used when the application of the finishing in question is the same as semimatte finishing but films must be given transparency or when the adhesion of sheets after forming must be prevented. Performing a different finishing process from semimatte finishing creates roll surfaces with fine air pockets while making them almost look like mirror-finished surfaces.

Mirror pocket finishing

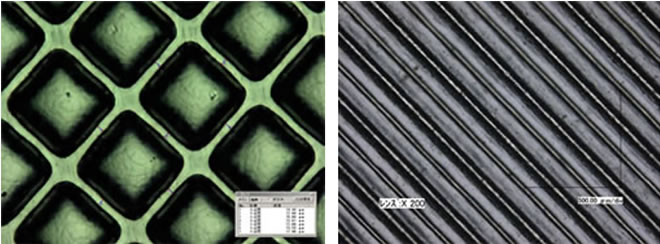

Embossing and engraving

We handle a variety of engraving on roll surfaces. There are a variety of engraving methods such as mill engraving and laser engraving, and we can handle a range of patterns in collaboration with our partner companies.

Embossing and engraving