Characteristics of Tfe-Lok

Thanks to the excellent non-adhesiveness, low coefficient of friction, and self-lubricating capabilities provided by polytetrafluoroethylene (PTFE) and the high rigidity of hard chrome plating, Tfe-Lok produces better mold releasability and wear resistance than normal chrome plating and other composite PTFE platings.

Wear characteristics of various composite films

Kinetic friction characteristics of various surface treatments

Because Tfe-Lok is based on chrome plating, its hardness is approximately Hv850.

The melting point of Tfe-Lok is below that (327°C) of PTFE. For continued use, we recommend that Tfe-Lok be used around 250°C.

Tfe-Lok complies with the Standards for Implements, Containers and Packaging that are based on the “Specifications and Standards for Food and Food Additives, etc., Under the Food Sanitation Act” (Notification No. 370 of the Japanese Ministry of Health, Labour, and Welfare). This means that Tfe-Lok can also be used in such a way that its surfaces come into direct contact with food. Note: Analytical experiments have already been conducted by Japan Food Research Laboratories. If you want a copy of the test result certificate, please send an inquiry form or phone us.

The treatment temperature of Tfe-Lok is as low as approximately 200°C, which means that there is almost no thermal influence on materials.

The surface roughness of the workpiece to be plated can be freely adjusted. (The maximum specularity is 1.0S.)

Tfe-Lok ensures dimensional accuracy and allows replating and partial plating.

Using nickel plating as an undercoating improves the corrosion resistance of Tfe-Lok.

Tfe-Lok can be detached and replated in the same way as normal chrome plating.

Materials that can be plated

Tfe-Lok can be applied to a wide range of metal materials including steel, stainless steel, aluminum, copper, copper alloys, nickel, and titanium.

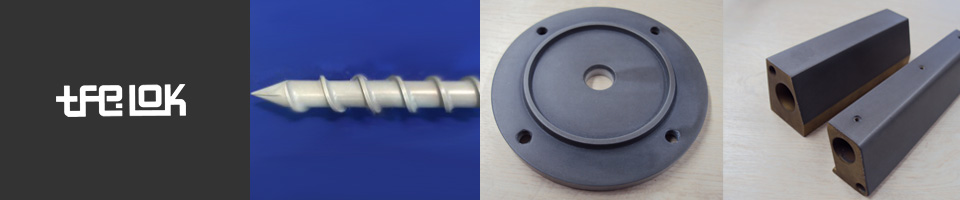

Uses of Tfe-Lok

One of the best features of Tfe-Lok is excellent mold releasability, which has enabled Tfe-Lok to be used for a variety of purposes, such as preventing sticking of resins, improving fluidity, and preventing adhesive wear, abrasion, and galling on steel plates during molding.

Practical uses

| Parts for molding plastic and rubber |

Dies, cores, nipples, die rings, adjusting rings, mandrels, molds, torpedos, beaker plates, screws, screw heads, laminated rolls, calendar rolls, press rolls, guide rolls, embossing rolls, T-shaped dies, crosshead dies, preheating rolls, cooling rolls, etc. |

| Parts for forming metal |

Dies (such as dies for drawing, bending, extruding, flanging, and spinning), punches, bushings, rollers, plates, guides, etc. |

| Parts for making food and medical products |

Hoppers, plates, guides, molds, pestles, mortars, cutters, cutter holders, rolls, screws, impellers, etc. |

| Packaging and logistics machinery parts |

Heat sealers, guides, hoppers, dies, mandrels, hot plates, chute guides, tables, carrier bars, etc. |

| Others |

Piston rods, bearings, cams, plungers, sewing machine parts, etc. |

Tfe-Lok features good lubricity, which means that using Tfe-Lok for molded plastic parts can improve the fluidity of resins and lower the molding pressure. Tfe-Lok also features excellent non-adhesiveness, thus improving productivity and maintainability through reduction in seizure of resins, as well as making it possible to use various types of resins with poor releasability. Thanks to these features, Tfe-Lok has been used in mandrels for molding PVC, dies for manufacturing rocket components, and various types of metal rolls.

Application examples of Tfe-Lok in the food industry include candy molds (pestles) requiring releasability, ham and cheese cutter plates, hoppers for coffee and sugar filling machines that aim for durability, slipperiness, and adhesion prevention, and pistons and cylinders for milk filling machines that require oil-free environments. In the pharmaceutical industry, Tfe-Lok is used for tablet guides and hoppers that aim for durability, slipperiness, and adhesion prevention. In these industries, the safety and functionality of Tfe-Lok are highly regarded.

Tfe-Lok is used for many packaging machinery parts such as heat sealers and guide parts. Aluminum and copper alloys with good thermal conductivity are mainly used for heat sealers, but their hardness is low and so they have no durability and their non-adhesiveness is not good either. Teflon coatings seem to be sometimes used, but their mechanical strength and thermal conductivity are not good and so their applications are limited. On the other hand, Tfe-Lok is based on chrome plating and thus provides good mechanical strength and thermal conductivity, and it also features non-adhesiveness provided by polytetrafluoroethylene (PTFE), thus enabling us to expect effects such as lowering the preset temperature, and improving durability and maintainability.

Adhesive wear, abrasion, galling, and other problems tend to easily occur to steel plates during molding, and so molding is often performed while a lubricant is being applied or sprayed. However, even if a lubricant is used, it is sometimes difficult to perform molding, depending on the molding conditions or some other factor. There are some cases where using Tfe-Lok for such parts makes it possible to perform molding.

Comparison between chrome plating and Tfe-Lok in regard to

their applications to expander molds

| Surface treatment |

Use of lubricant |

Result of molding |

Variation in can diameter |

| Chrome plating |

None |

Ruptures or

cracks occur. |

- |

| Chrome plating |

Continuous waxing |

Ruptures or cracks occur when approximately 100,000 cans are molded. |

Difference in can diameter between the first can and the can before rupture: 3 mm |

| Tfe-Lok |

None |

No rupture occurs even when more than 100,000 cans are molded. |

Difference in can diameter between the first can and the can before rupture:Approx. 1 mm or less |

| Tfe-Lok |

Fatty acid ester |

No rupture occurs even when more than 100,000 cans are molded. |

Difference in can diameter between the first can and the can before rupture:Approx. 1 mm or less |

| Tfe-Lok |

Paraffin wax |

No rupture occurs even when more than 100,000 cans are molded. |

Difference in can diameter between the first can and the can before rupture:Approx. 0.5 mm or less |

Maximum applicable size for Tfe-Lok

The overall length must be no more than 3,500 mm. (For any size greater than the maximum limit, please consult with Otec.)